steve_bank

Diabetic retinopathy and poor eyesight. Typos ...

Conflict in the cockpit has caused accidents. A recoverable problem ends in a crash because pilot and copilot disagree.

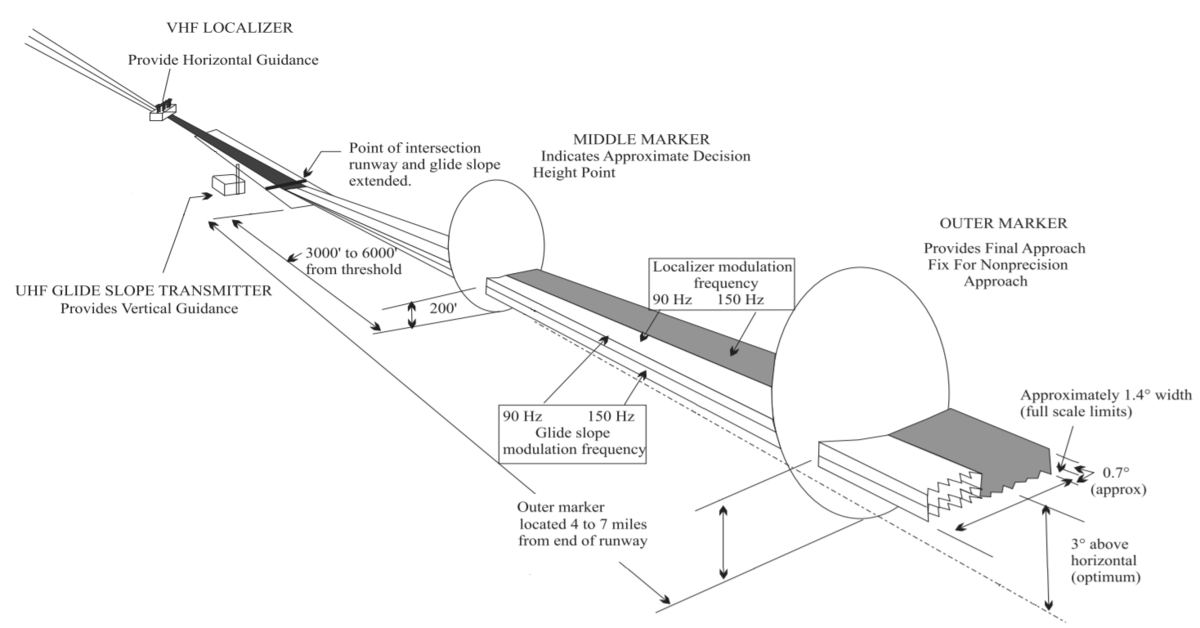

Pilots flying IFR today still rely on ground based VORs for navigation, with GPS and INS (if they have it) as secondary sources. Approaches using ground based ILS and glideslope are considered precision approaches (there are different categories depending on the nature of the hardware on the ground and in the airplane), while flying approaches using GPS is considered a non-precision approach. The minimums are different for precision versus non-precision, and higher for the latter. Modern commercial jets can even do autoland if the appropriate hardware is available on the runway with very low minimums (50 to 100 feet).When you fly on instruments there are stacked altitudes that go in different directions. Before GPS you would fly between VOR radio beacons.

More my experience is that pilots are required to learn and use autoland. It's not a matter of "can" as much as "are supposed to".Pilots flying IFR today still rely on ground based VORs for navigation, with GPS and INS (if they have it) as secondary sources. Approaches using ground based ILS and glideslope are considered precision approaches (there are different categories depending on the nature of the hardware on the ground and in the airplane), while flying approaches using GPS is considered a non-precision approach. The minimums are different for precision versus non-precision, and higher for the latter. Modern commercial jets can even do autoland if the appropriate hardware is available on the runway with very low minimums (50 to 100 feet).When you fly on instruments there are stacked altitudes that go in different directions. Before GPS you would fly between VOR radio beacons.

en.wikipedia.org

en.wikipedia.org

In aviation, the instrument landing system (ILS) is a radio navigation system that provides short-range guidance to aircraft to allow them to approach a runway at night or in bad weather. In its original form, it allows an aircraft to approach until it is 200 feet (61 m) over the ground, within a 1⁄2 mile (800 m) of the runway. At that point the runway should be visible to the pilot; if it is not, they perform a missed approach. Bringing the aircraft this close to the runway dramatically improves the weather conditions in which a safe landing can be made. Later versions of the system, or "categories", have further reduced the minimum altitudes.

The advent of the Global Positioning System (GPS) provides an alternative source of approach guidance for aircraft. In the US, the Wide Area Augmentation System (WAAS) has been available in many regions to provide precision guidance to Category I standards since 2007. The equivalent European Geostationary Navigation Overlay Service (EGNOS) was certified for use in safety of life applications in March 2011.[27] As such, the number of Cat I ILS systems may be reduced, however there are no plans in the United States to phase out any Cat II or Cat III systems.[28]

Local Area Augmentation System (LAAS) is under development to provide for Category III minimums or lower. The FAA Ground-Based Augmentation System (GBAS) office is currently working with the industry in anticipation of the certification of the first GBAS ground stations in Memphis, TN; Sydney, Australia; Bremen, Germany; Spain; and Newark, NJ. All four countries have installed GBAS systems and are involved in technical and operational evaluation activities.

The Honeywell and FAA team obtained System Design Approval of the world's first non-federal U.S. approval for LAAS Category I at Newark Liberty International Airport, operations on September 2009 and Operational Approval on September 28, 2012.[29]

In Norway, a D-GPS based landing system, called SCAT-I, is in operation on some short runway airports.

en.wikipedia.org

en.wikipedia.org

The microwave landing system (MLS) is an all-weather, precision radio guidance system intended to be installed at large airports to assist aircraft in landing, including 'blind landings'. MLS enables an approaching aircraft to determine when it is aligned with the destination runway and on the correct glidepath for a safe landing. MLS was intended to replace or supplement the instrument landing systems (ILS). MLS has a number of operational advantages over ILS, including a wider selection of channels to avoid interference with nearby installations, excellent performance in all weather, a small "footprint" at the airports, and wide vertical and horizontal "capture" angles that allowed approaches from wider areas around the airport.

Although some MLS systems became operational in the 1990s, the widespread deployment envisioned by some aviation agencies never became a reality. There were two reasons: (economic) while technically superior to ILS, MLS did not offer sufficiently greater capabilities to justify adding MLS receivers to aircraft equipage; and (potentially superior third system) GPS-based systems, notably WAAS, allowed the expectation of a similar level of positioning with no equipment needed at the airport. GPS/WAAS dramatically lowers an airport's cost of implementing precision landing approaches, which is particularly important at small airports. For these reasons, most existing MLS systems in North America have been turned off. GPS/WAAS-based LPV 'Localizer Performance with Vertical guidance' approaches provide vertical guidance comparable to ILS Category I and FAA-published LPV approaches currently outnumber ILS approaches at US airports.

Though initially MLS appeared to be of interest in Europe, where concerns over the availability of GPS were an issue, widespread installation never occurred. Further deployment of the system is not likely. Rather, several European airports have implemented LPV approaches based on the EGNOS (WAAS-compatible) satellite system.

In the United States, the FAA suspended the MLS program in 1994 in favor of the GPS (Wide Area Augmentation System WAAS). The FAA's inventory of instrument flight procedures no longer includes any MLS locations;[7] the last two were eliminated in 2008.

en.wikipedia.org

en.wikipedia.org

The Wide Area Augmentation System (WAAS) is an air navigation aid developed by the Federal Aviation Administration to augment the Global Positioning System (GPS), with the goal of improving its accuracy, integrity, and availability. Essentially, WAAS is intended to enable aircraft to rely on GPS for all phases of flight, including precision approaches to any airport within its coverage area.[1] It may be further enhanced with the Local Area Augmentation System (LAAS) also known by the preferred ICAO term Ground-Based Augmentation System (GBAS) in critical areas.

WAAS uses a network of ground-based reference stations, in North America and Hawaii, to measure small variations in the GPS satellites' signals in the western hemisphere. Measurements from the reference stations are routed to master stations, which queue the received Deviation Correction (DC) and send the correction messages to geostationary WAAS satellites in a timely manner (every 5 seconds or better). Those satellites broadcast the correction messages back to Earth, where WAAS-enabled GPS receivers use the corrections while computing their positions to improve accuracy.

The International Civil Aviation Organization (ICAO) calls this type of system a satellite-based augmentation system (SBAS). Europe and Asia are developing their own SBASs, the Indian GPS Aided Geo Augmented Navigation (GAGAN), the European Geostationary Navigation Overlay Service (EGNOS), the Japanese Multi-functional Satellite Augmentation System (MSAS) and the Russian System for Differential Corrections and Monitoring (SDCM), respectively. Commercial systems include StarFire, OmniSTAR, and Atlas.

What experience do you have on this subject? Are you a commercial pilot?More my experience is that pilots are required to learn and use autoland. It's not a matter of "can" as much as "are supposed to".Pilots flying IFR today still rely on ground based VORs for navigation, with GPS and INS (if they have it) as secondary sources. Approaches using ground based ILS and glideslope are considered precision approaches (there are different categories depending on the nature of the hardware on the ground and in the airplane), while flying approaches using GPS is considered a non-precision approach. The minimums are different for precision versus non-precision, and higher for the latter. Modern commercial jets can even do autoland if the appropriate hardware is available on the runway with very low minimums (50 to 100 feet).When you fly on instruments there are stacked altitudes that go in different directions. Before GPS you would fly between VOR radio beacons.

All my experience is in programming autoland systems and associated avionics/position systems data processes for simulators, so discussing with commercial pilots on the context of autoland, particularly cat3, as it was my job to accurately program a system that represented and satisfied the decision tree on cat3 autoland conditions.What experience do you have on this subject? Are you a commercial pilot?More my experience is that pilots are required to learn and use autoland. It's not a matter of "can" as much as "are supposed to".Pilots flying IFR today still rely on ground based VORs for navigation, with GPS and INS (if they have it) as secondary sources. Approaches using ground based ILS and glideslope are considered precision approaches (there are different categories depending on the nature of the hardware on the ground and in the airplane), while flying approaches using GPS is considered a non-precision approach. The minimums are different for precision versus non-precision, and higher for the latter. Modern commercial jets can even do autoland if the appropriate hardware is available on the runway with very low minimums (50 to 100 feet).When you fly on instruments there are stacked altitudes that go in different directions. Before GPS you would fly between VOR radio beacons.

Assuming you are talking about pilots flying under a commercial license, they are trained to use Autoland if the equipment they fly offers this feature. This training would be required to get their type rating. Most smaller airplanes do not have Autoland, although a couple of manufacturers have introduced an Emergency Autoland feature in their recent models, which is not the same thing as the Autoland feature found on larger commercial aircraft.

It is the tower controller/airport who has the final say in what approaches pilots can use to land on specific runways. In practice, the pilot can request a preferred approach, and the tower may allow it if conditions allow. For commercial flights, a vast majority of approaches use Cat 1 ILS with glideslope or visual with RNAV guidance. And every commercial airline has their own policies and procedures that the pilots are required to follow. The Autoland approach is a Cat 3 precision approach, and many airports don't have the hardware to support Cat 3. Autoland requires the flight directors, autopilots and associated systems on the airplane to be fully functional without any degradation (which may not be the case if the aircraft is experiencing technical problems). The Autoland feature also imposes limitations on the spacing of aircraft in the pattern, which makes it impractical for busy airports. Autoland is used when the cloud ceiling is too low (or IMC at the surface) to allow a Cat 1 or 2 approach, and the airplane has a problem that requires them to get on the ground quickly. I believe most airlines require their pilots to fly to their alternate where they can do a Cat 1 or visual approach instead of flying a Cat 3 Autoland at the original destination. Autoland is NOT a recommended procedure, but more of a last resort.

I worked on avionics, magnetic proximity detection systems and true mass fuel flow rate sensors. Variable reluctance magnetic proximity is used to sense mechancal postion in harsh enviromnet like flap positions. A critcal function was sensing reverse thrusters deploying in flight and activating a backup restow function. Eldec in the Seattle area. I was out at Boeing once and a while craswling around the avionics bay. 777 and 757-300.All my experience is in programming autoland systems and associated avionics/position systems data processes for simulators, so discussing with commercial pilots on the context of autoland, particularly cat3, as it was my job to accurately program a system that represented and satisfied the decision tree on cat3 autoland conditions.What experience do you have on this subject? Are you a commercial pilot?More my experience is that pilots are required to learn and use autoland. It's not a matter of "can" as much as "are supposed to".Pilots flying IFR today still rely on ground based VORs for navigation, with GPS and INS (if they have it) as secondary sources. Approaches using ground based ILS and glideslope are considered precision approaches (there are different categories depending on the nature of the hardware on the ground and in the airplane), while flying approaches using GPS is considered a non-precision approach. The minimums are different for precision versus non-precision, and higher for the latter. Modern commercial jets can even do autoland if the appropriate hardware is available on the runway with very low minimums (50 to 100 feet).When you fly on instruments there are stacked altitudes that go in different directions. Before GPS you would fly between VOR radio beacons.

Assuming you are talking about pilots flying under a commercial license, they are trained to use Autoland if the equipment they fly offers this feature. This training would be required to get their type rating. Most smaller airplanes do not have Autoland, although a couple of manufacturers have introduced an Emergency Autoland feature in their recent models, which is not the same thing as the Autoland feature found on larger commercial aircraft.

It is the tower controller/airport who has the final say in what approaches pilots can use to land on specific runways. In practice, the pilot can request a preferred approach, and the tower may allow it if conditions allow. For commercial flights, a vast majority of approaches use Cat 1 ILS with glideslope or visual with RNAV guidance. And every commercial airline has their own policies and procedures that the pilots are required to follow. The Autoland approach is a Cat 3 precision approach, and many airports don't have the hardware to support Cat 3. Autoland requires the flight directors, autopilots and associated systems on the airplane to be fully functional without any degradation (which may not be the case if the aircraft is experiencing technical problems). The Autoland feature also imposes limitations on the spacing of aircraft in the pattern, which makes it impractical for busy airports. Autoland is used when the cloud ceiling is too low (or IMC at the surface) to allow a Cat 1 or 2 approach, and the airplane has a problem that requires them to get on the ground quickly. I believe most airlines require their pilots to fly to their alternate where they can do a Cat 1 or visual approach instead of flying a Cat 3 Autoland at the original destination. Autoland is NOT a recommended procedure, but more of a last resort.

The issue was that in the condition, the simulator was failing to do cat3 autoland, and that this was a major concern for the customer.

My memory is not great though? Maybe I am remembering wrong? I only spent a month or two out of 6 years on passenger plane simulators on the autoland DR.

I've probably crashed that simulator more than I've gotten it down.

I also spent a long time reverse engineering B787 avionics and control package code so we could properly implement an operating system for it, and digging through fault decision trees in assembly code, often from one entire system through to another. That one is more like 2-3 of those 6 years.

Then 2 years programming firmware for low budget flight control panels.for.simulator use, and the rest of it programming various positional system elements, like IRU alignment logic and the like.

The fault trees in assembly were that way because we only were able to get binaries from Boeing, and getting licenses for and working in VxWorks653 (I think that's the number? It's been a minute) to RE elements of the OS would cause us to need to license that and that was judged not cost effective. Instead we took GHS, and implemented an Arinc 653 layer, but to get all of it working properly, we had to RE the binaries themselves for their system call requirements and behaviors, as well as get the queuing and message structure built into the GHS OS model.I worked on avionics, magnetic proximity detection systems and true mass fuel flow rate sensors. Variable reluctance magnetic proximity is used to sense mechancal postion in harsh enviromnet like flap positions. A critcal function was sensing reverse thrusters deploying in flight and activating a backup restow function. Eldec in the Seattle area. I was out at Boeing once and a while craswling around the avionics bay. 777 and 757-300.All my experience is in programming autoland systems and associated avionics/position systems data processes for simulators, so discussing with commercial pilots on the context of autoland, particularly cat3, as it was my job to accurately program a system that represented and satisfied the decision tree on cat3 autoland conditions.What experience do you have on this subject? Are you a commercial pilot?More my experience is that pilots are required to learn and use autoland. It's not a matter of "can" as much as "are supposed to".Pilots flying IFR today still rely on ground based VORs for navigation, with GPS and INS (if they have it) as secondary sources. Approaches using ground based ILS and glideslope are considered precision approaches (there are different categories depending on the nature of the hardware on the ground and in the airplane), while flying approaches using GPS is considered a non-precision approach. The minimums are different for precision versus non-precision, and higher for the latter. Modern commercial jets can even do autoland if the appropriate hardware is available on the runway with very low minimums (50 to 100 feet).When you fly on instruments there are stacked altitudes that go in different directions. Before GPS you would fly between VOR radio beacons.

Assuming you are talking about pilots flying under a commercial license, they are trained to use Autoland if the equipment they fly offers this feature. This training would be required to get their type rating. Most smaller airplanes do not have Autoland, although a couple of manufacturers have introduced an Emergency Autoland feature in their recent models, which is not the same thing as the Autoland feature found on larger commercial aircraft.

It is the tower controller/airport who has the final say in what approaches pilots can use to land on specific runways. In practice, the pilot can request a preferred approach, and the tower may allow it if conditions allow. For commercial flights, a vast majority of approaches use Cat 1 ILS with glideslope or visual with RNAV guidance. And every commercial airline has their own policies and procedures that the pilots are required to follow. The Autoland approach is a Cat 3 precision approach, and many airports don't have the hardware to support Cat 3. Autoland requires the flight directors, autopilots and associated systems on the airplane to be fully functional without any degradation (which may not be the case if the aircraft is experiencing technical problems). The Autoland feature also imposes limitations on the spacing of aircraft in the pattern, which makes it impractical for busy airports. Autoland is used when the cloud ceiling is too low (or IMC at the surface) to allow a Cat 1 or 2 approach, and the airplane has a problem that requires them to get on the ground quickly. I believe most airlines require their pilots to fly to their alternate where they can do a Cat 1 or visual approach instead of flying a Cat 3 Autoland at the original destination. Autoland is NOT a recommended procedure, but more of a last resort.

The issue was that in the condition, the simulator was failing to do cat3 autoland, and that this was a major concern for the customer.

My memory is not great though? Maybe I am remembering wrong? I only spent a month or two out of 6 years on passenger plane simulators on the autoland DR.

I've probably crashed that simulator more than I've gotten it down.

I also spent a long time reverse engineering B787 avionics and control package code so we could properly implement an operating system for it, and digging through fault decision trees in assembly code, often from one entire system through to another. That one is more like 2-3 of those 6 years.

Then 2 years programming firmware for low budget flight control panels.for.simulator use, and the rest of it programming various positional system elements, like IRU alignment logic and the like.

What language did you use to do embedded avionic code? Fault trees in assembly language? What was the processor?

I was a reliability engineer in one incarnation. Are you familiar with FMECA?

Oh, the flight systems I worked on implementation on PPC, those were entirely aircraft software parts, the assembly code I dug through exactly the software that goes on the plane, the operating systems that go on the maintenance laptops, the software that signs the software parts.So, when you say simulator you mean video games and you never coded for flight avionics and you never actualy worked on flight sytems?

Somebody once told me everybody bullshits a little. I think he was right, some more than others.

I assume you were working on software for Class D sims, the machines that are used to train commercial pilots for their type rating. Is that correct?All my experience is in programming autoland systems and associated avionics/position systems data processes for simulators, so discussing with commercial pilots on the context of autoland, particularly cat3, as it was my job to accurately program a system that represented and satisfied the decision tree on cat3 autoland conditions.

A few different simulator types, actually. The most common I worked on were training devices preparing someone for a full-flight. Full-flight sim hours are expensive and cheaper devices that don't use actual aircraft hardware are useful for that. They still have to fly the magenta line, as it were, all the systems have to behave and fault the same way aircraft systems do, all the geometry and trig of how radio stations are moved, periodically broadcast and position is trilaterated have to be dealt with, and interesting enough, you get to see more of that working on the non-full-flights since the full flight sim uses aircraft panels that are programmed from the airlines to do all those tasks.I assume you were working on software for Class D sims, the machines that are used to train commercial pilots for their type rating. Is that correct?All my experience is in programming autoland systems and associated avionics/position systems data processes for simulators, so discussing with commercial pilots on the context of autoland, particularly cat3, as it was my job to accurately program a system that represented and satisfied the decision tree on cat3 autoland conditions.

I have never flown a jet, but I have 3.5 hours in a 737NG Class D sim. I won a raffle at my FBO and went to Orlando for a whole day of "training", which was the prize. Spent the morning in the classroom learning about flight control systems, and the afternoon in a sim with a CFI. It was incredible fun, and the only time I will get to pilot a large turbofan airplane. We did basic navigation, programming the plan, a departure with a complicated plan to avoid terrain, and at the end we flew a complete approach into Runway 22R at KJFK. Handflew the airplane all the way from the 6-mile marker following the localizer and glideslope and put it down on the centerline at the markers, as gentle as a feather. The CFI said I was a natural. A perfect end to a perfect day.